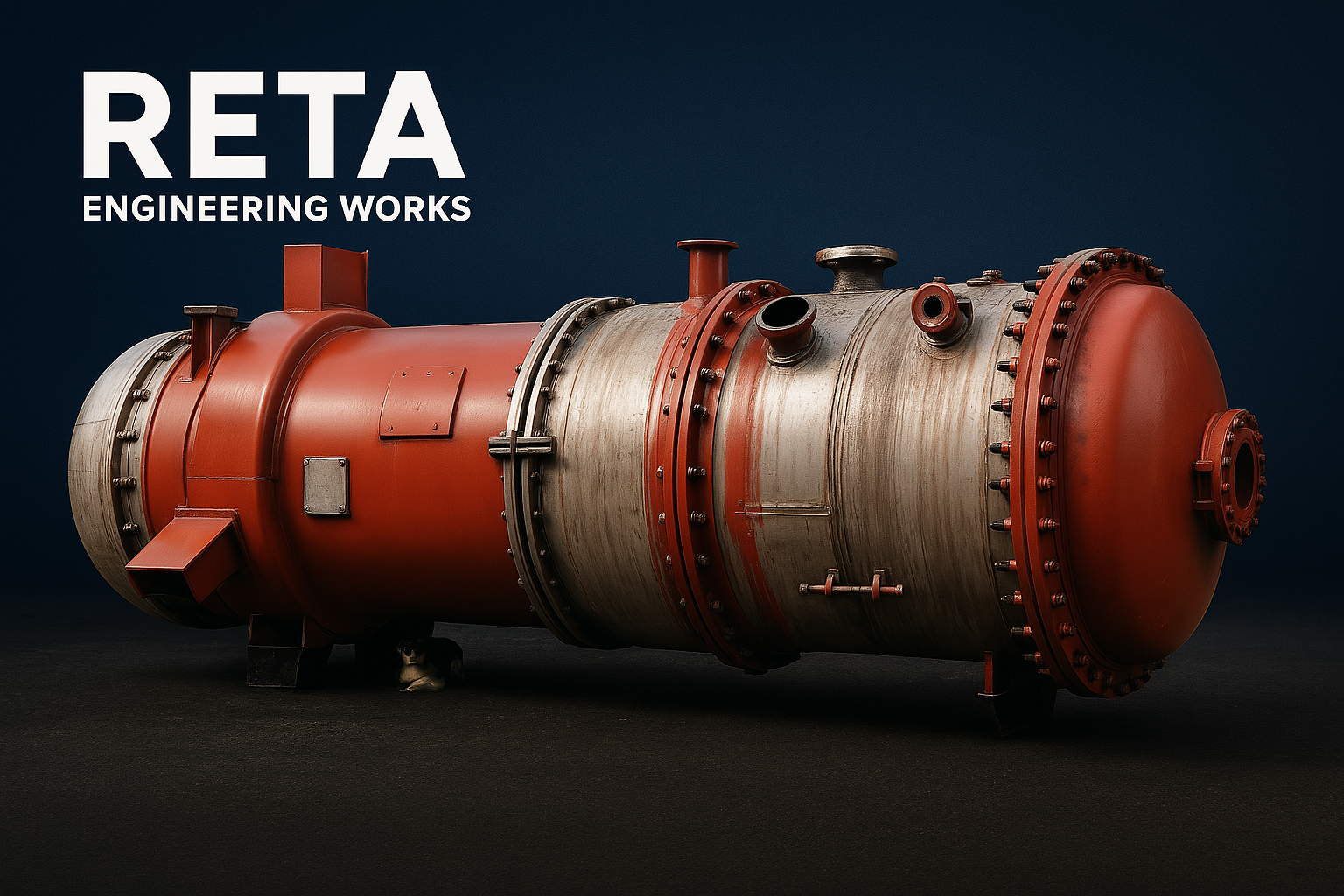

Reta Engineering Works is among the most trusted manufacturers of MS and Stainless Steel pressure vessels in India, delivering solutions that meet ASME Section VIII Div 1, IS 2825, and other international design codes. Our vessels are designed for safe containment of gases, liquids, steam, and chemicals under pressure and are widely used across chemical, pharmaceutical, petrochemical, agro, and process industries.

Whether you require storage-only vessels or complex systems integrated with process equipment, Reta Engineering provides custom-built pressure vessels with proven durability, leak-proof fabrication, and compliance with the highest safety standards.

While both pressure vessels and reactors are designed to handle pressurized operations, their applications and features are different:

👉 Looking for chemical reactors instead? Explore our complete range of Reactors Here.

| Feature | Specification |

|---|---|

| Design Codes | ASME Sec VIII Div 1, IS 2825, IS 803 |

| Capacity | 500L – 100,000L |

| Material | Mild Steel, SS 304, SS 316, Alloy Steels |

| Thickness | 3mm – 50mm |

| Pressure Rating | Vacuum to 350 bar |

| End Type | Flat / Conical / Elliptical / Torispherical |

| Testing | Hydro Test, NDT, Radiography, Leak Testing |

| Surface Finish | Polished / Painted / Rubber-Lined / FRP Coated |

Our pressure vessels are trusted by industries where high safety, durability, and compliance are critical. From pharmaceutical and chemical plants to refineries, agro-processing, food & beverage, and power plants – Reta Engineering delivers precision-engineered solutions across India and abroad.

"The pressure vessels are built with precision and have passed all compliance and safety checks."

"Reta Engineering delivers high-performance pressure vessels that run flawlessly for years."